-

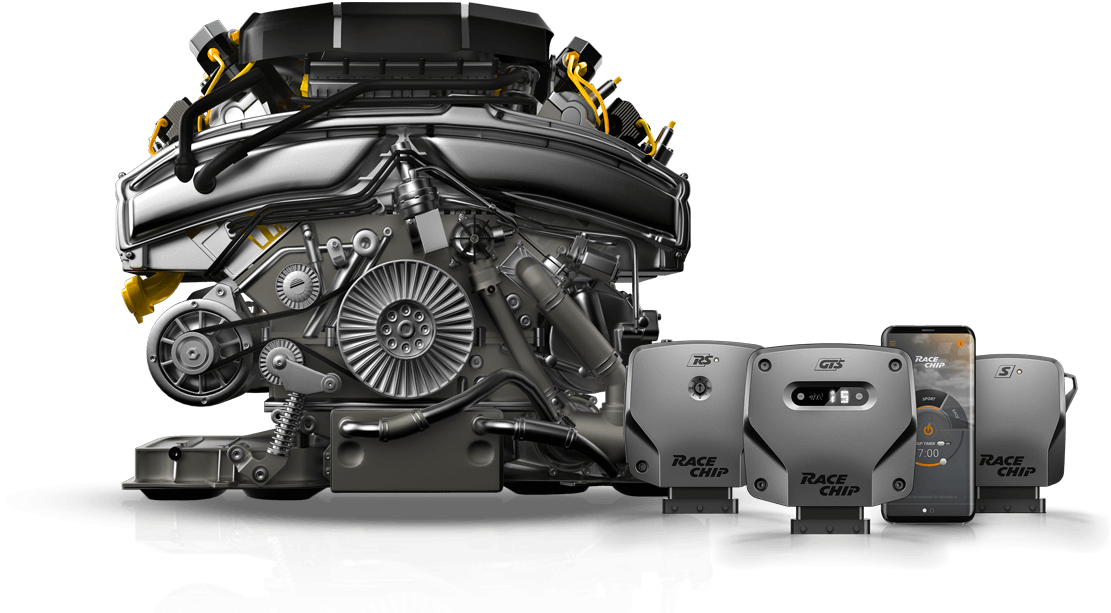

Here's how our chip tuning products work

-

Optimizing common rail turbo diesels – an explanation

Modern, turbo-charged diesel engines use sensors to collect, monitor and transmit important information to the electronic control unit (ECU). Then, based on the data measurements, the ECU sends commands to various engine components like the fuel injection system.

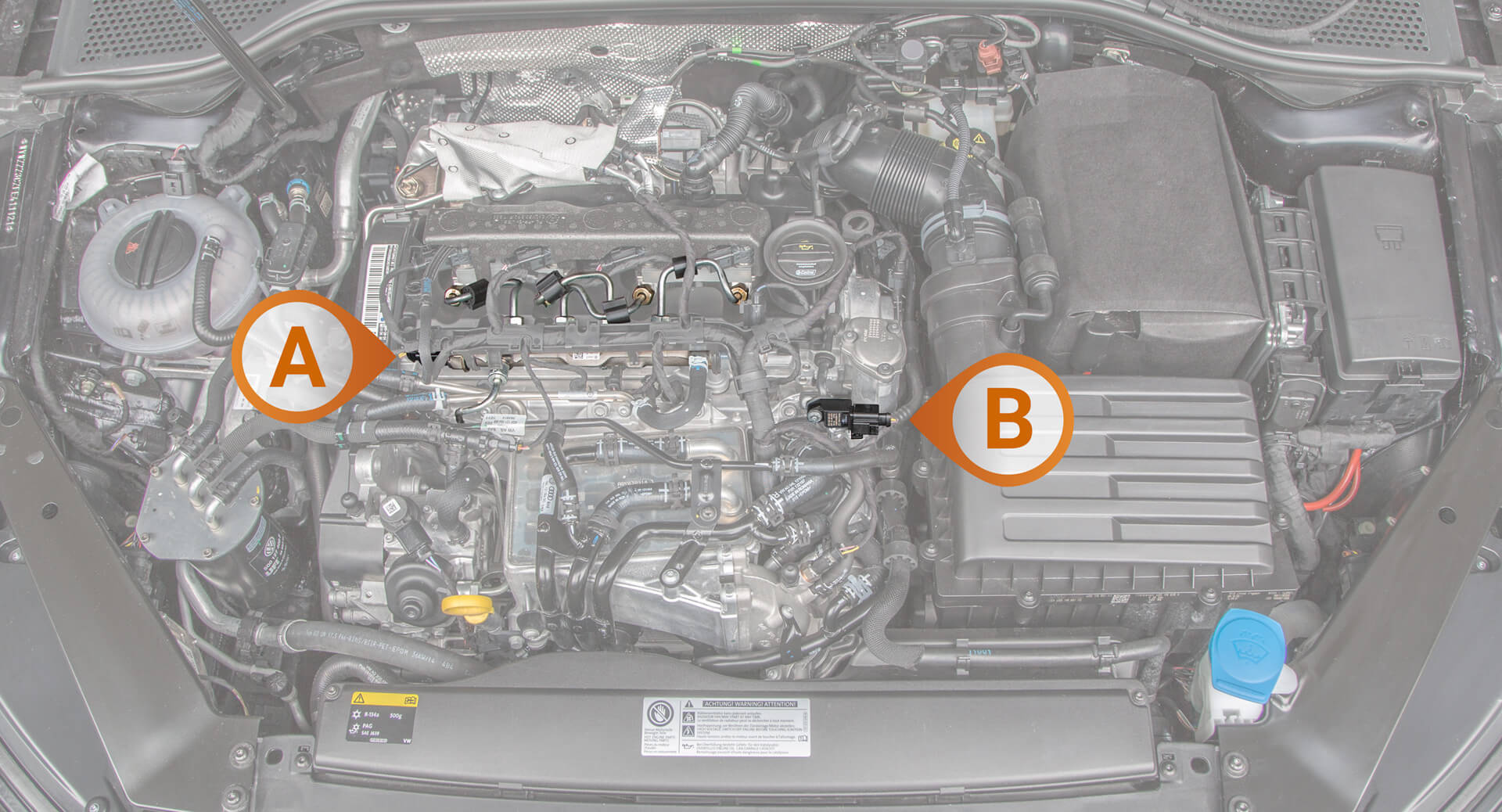

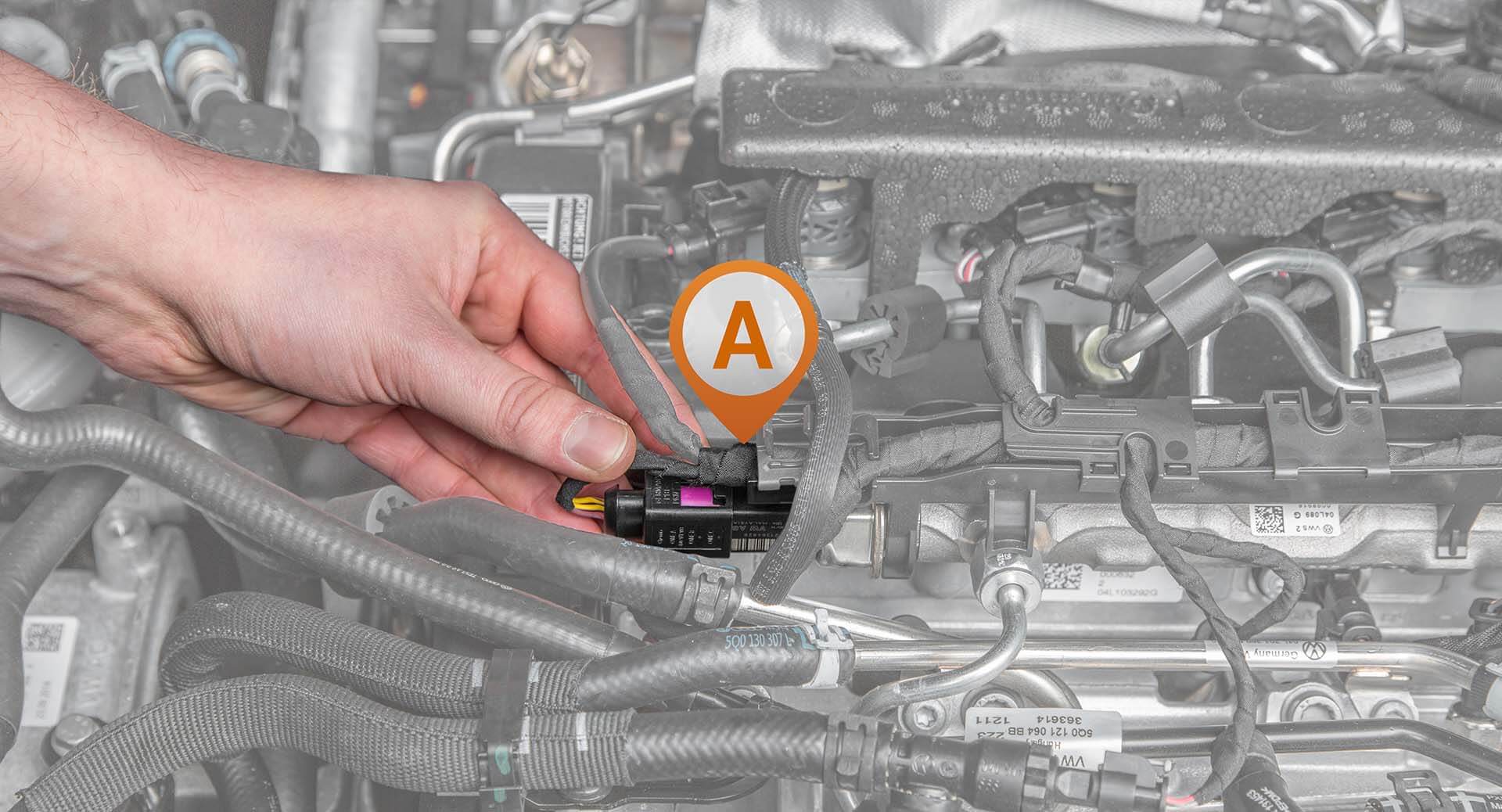

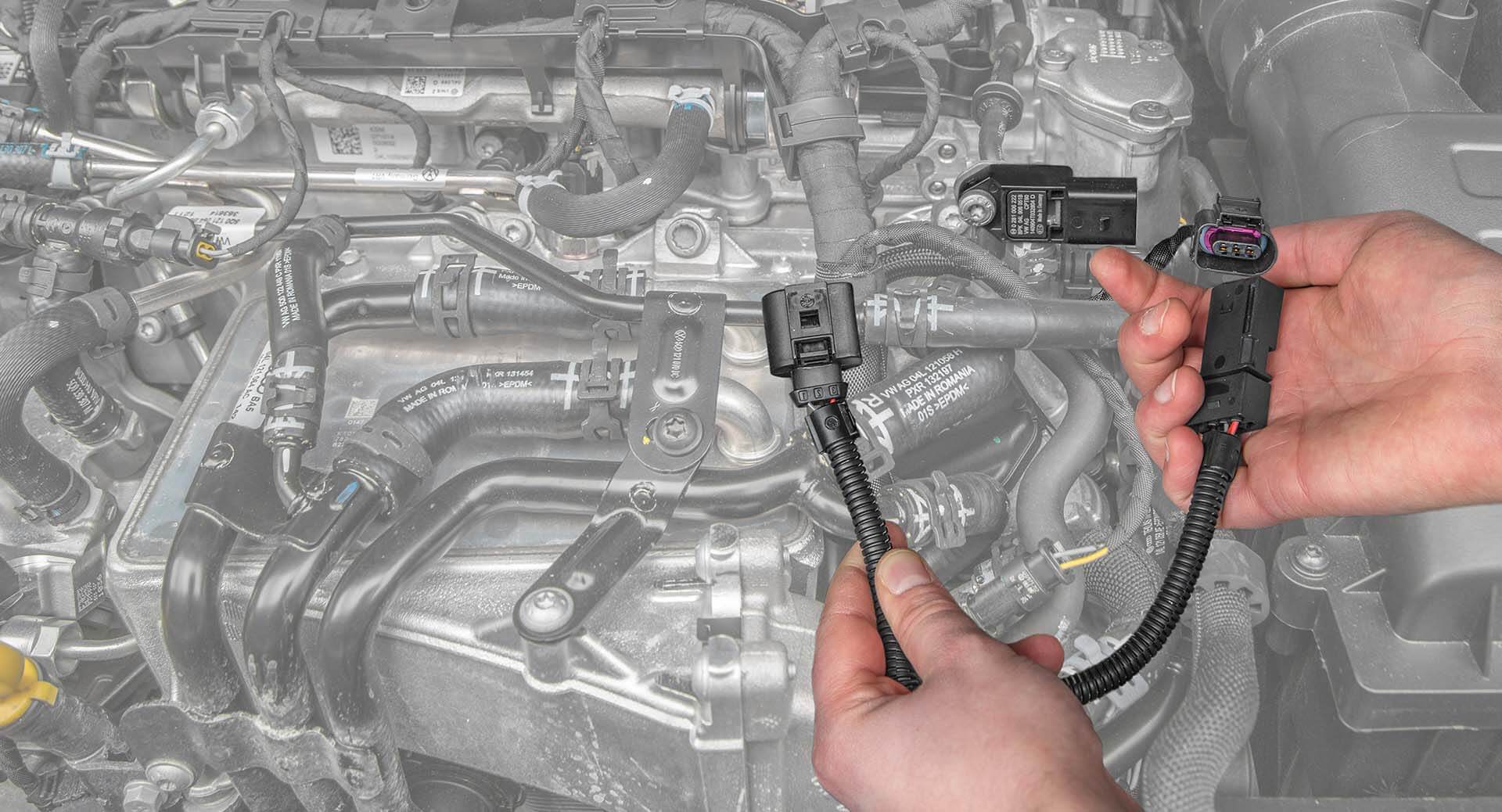

This is precisely where RaceChip common rail tuning comes into play. Our supplementary control unit directly reads the information from common rail pressure and turbo-charge pressure sensors like fuel injection pressure, fuel injection quantity, injection frequency and turbo-charge pressure. The signals are optimized in real time by our optimization software and then transmitted to your vehicle's ECU. At the same time, the ECU adjusts all of the other relevant parameters in the engine to the new, optimized values. The decisive advantage is that the manufacturer's ECU always has full control over all of the engine control parameters.

Signal optimization leads to an increase in the fuel injection quantity, injection pressure and - to a slight extent - the turbo-charge pressure. This increases the fuel compression along with the energy released through combustion. The increased fuel injection quantity further supports this effect.

The engine's overall efficiency factor and power potential increases significantly. For you, this means more power and a whole new level of driving experience.

-

Optimizing pump-nozzle turbo diesels - an explanation

In diesel engines using pump-nozzle technology (used primarily in vehicles from the Volkswagen Group between 2000 and 2009) performance improvement is achieved by increasing the fuel injection quantity as well as a temporary increase in boost pressure.

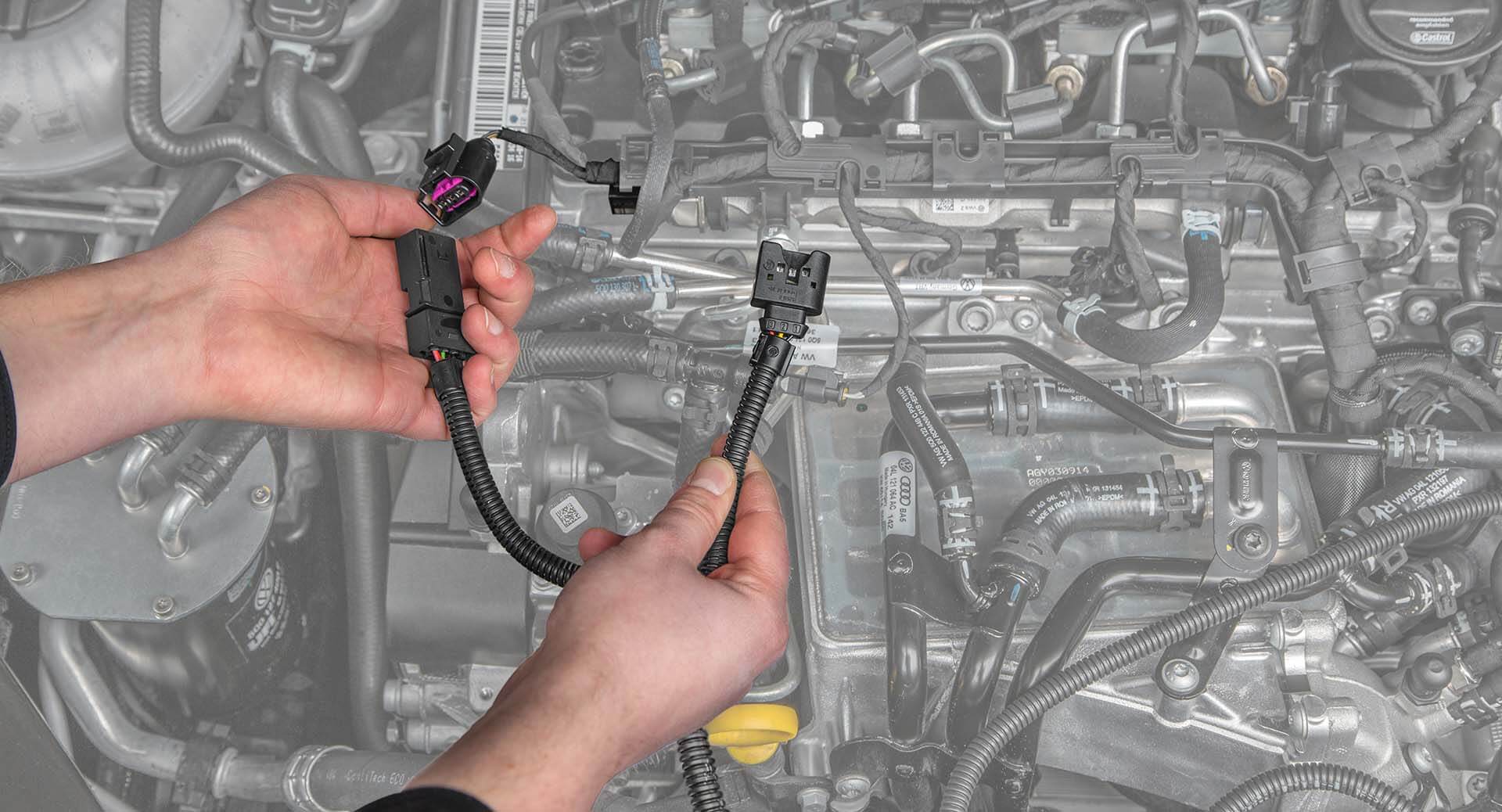

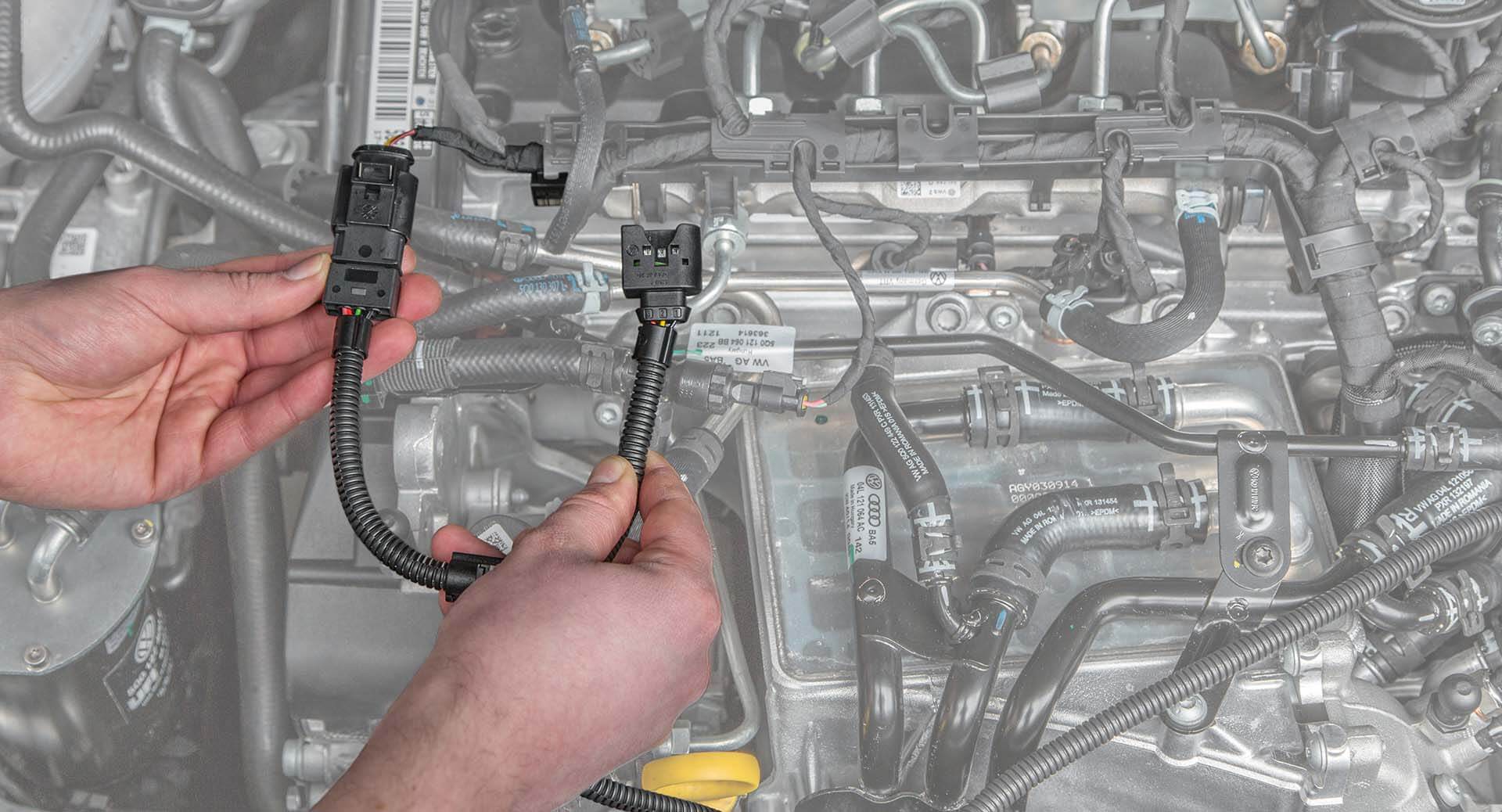

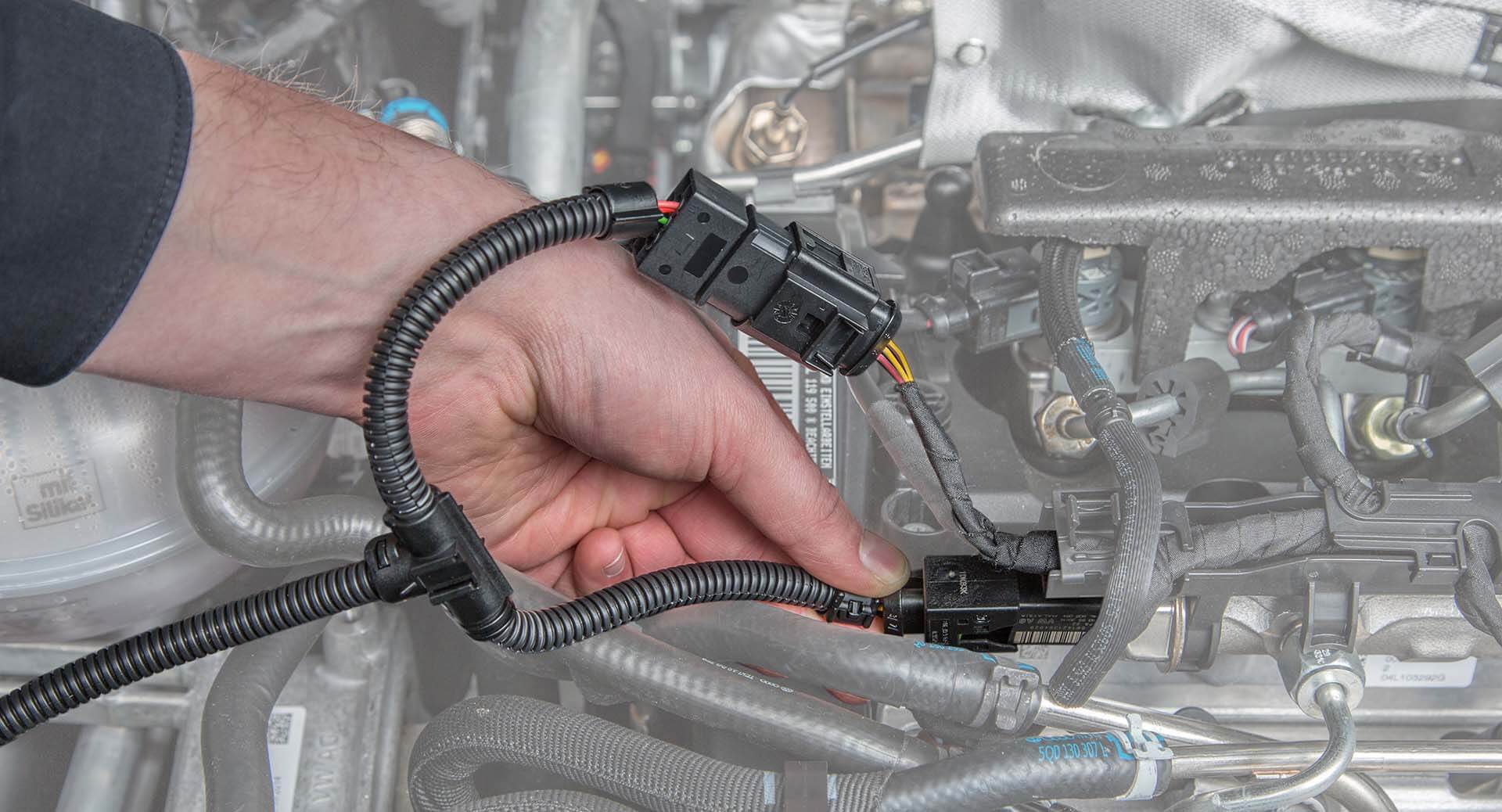

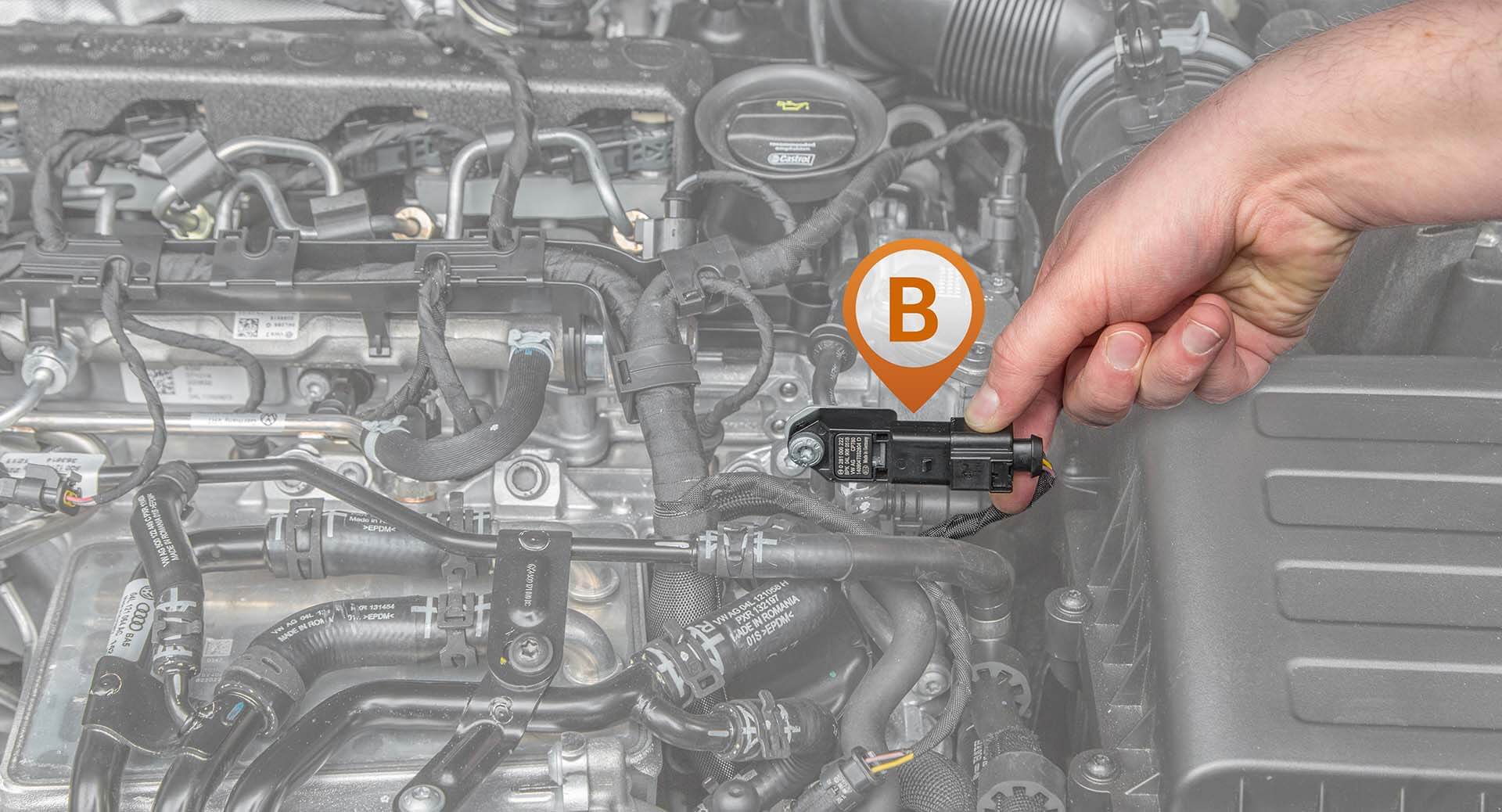

The supplementary control unit is directly connected to the injectors via the wiring harness. In this way, and the chip tuning module directly reads the fuel injection commands from the ECU and adjusts them according to our optimization software. The somewhat higher fuel injection quantity leads to a slight increase in the boost pressure.

Your vehicle's ECU then calculates the new values based on the optimized data and transmits them to your engine.

At the same time, all of the other relevant engine parameters are adjusted to the new, optimized values. The decisive benefit is that the manufacturer's ECU always has full control over all of the engine control parameters.

Overall you achieve a considerably higher level of engine performance.

-

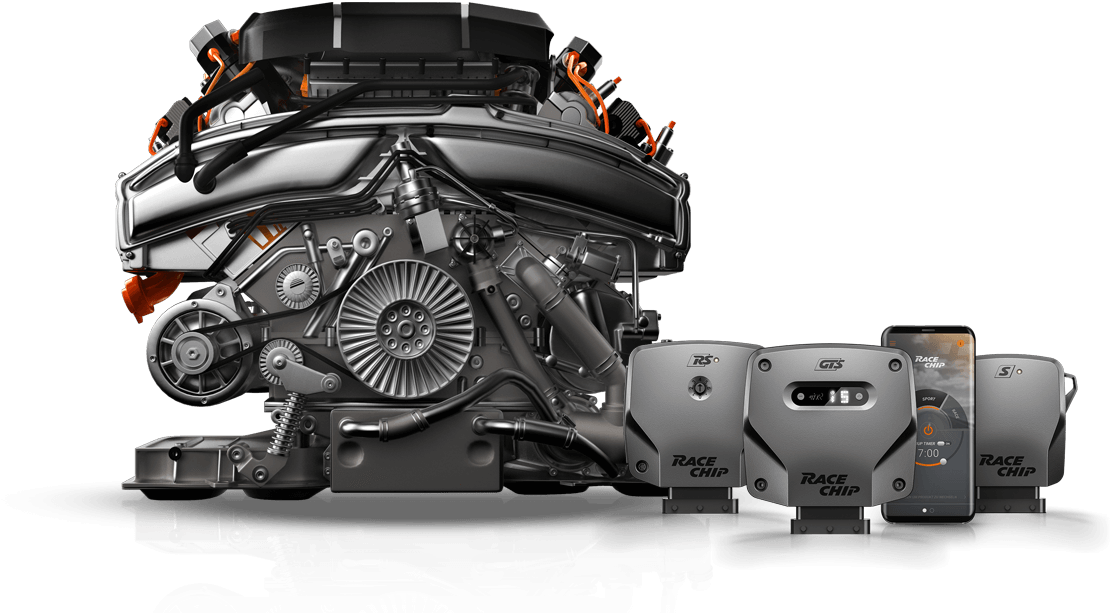

Optimizing turbo-charged petrol engines – an explanation

Modern Otto and petrol engines use sensors to collect and monitor a variety of parameters during operation. The data flows to an ECU and is processed there. Fuel injection quantity, boost pressure and air mass are the decisive factors in RaceChip performance improvement.

To improve the performance of super-charged petrol direct injection engines (regardless whether with turbo-chargers or compressors), our chip tuning module must read and revise the relevant parameters. We use data from the boost pressure sensor, the intake manifold pressure sensor and air mass sensor. The chip tuning software module processes in real time and then transmits the optimized data to the corresponding control sensors in your vehicle. The result is a considerable power boost you can feel – by increasing the boost pressure, adjusting the fuel injection angle, and slightly increasing the fuel injection quantity.

To increase the boost pressure, the turbine RPM is increased within a range defined by us, which increases your engines efficiency level. This provides more air for the engine, which allows the ignition timing to be adjusted more precisely and makes combustion in the cylinder more effective. Because more air is available for combustion, the fuel injection quantity must be increased somewhat for the ideal fuel-air mix in the combustion chamber.

More power and higher efficiency levels for your engine are the results of this precisely fine-tuned interplay between many factors. In doing so, all of the relevant engine data is continually collected and tested for plausibility in real time.

Because the integrated safety systems in your engine always maintain control with RaceChip car tuning software, they can kick in if variations ever occur. This ensures that you and your engine are always on the safe side.

A B C D E FG H I J K LM N O P Q RS T U V W XYZCommon Rail technology is used today in most turbo-charged diesel direct injection engines. The central feature of this technology is that a high pressure pump is used to generate pressure that is used to inject diesel directly into the combustion chamber with the injectors. This pressure is generated centrally for all injectors and is then sent accordingly to each one. This creates a very good fuel-air mix for injection.

The discovery of the combustion engine ushered in the age of the automobile. Since then, engines have developed enormously but still follow the basic function of the original combustion engine. A mix of fuel and air is ignited in a combustion chamber and the energy released by the controlled explosion generates kinetic energy. Today, there are two basic variations of combustion technology: non-turbo-charged engines (called aspirated engines, which are still used in several petrol engines) and turbo-charged piston engines (compressors and turbo-charged engines; modern diesel motors are based on this technology and, increasingly, petrol engines to further increase fuel efficiency). For non-turbo-charged engines (aspirated engines), the pistons create low pressure in the intake system, into which the air then flows. With increasing RPMs, this low pressure is insufficient to feed the maximum possible amount of air or fuel-air mixture into the combustion chamber and limits the power that the engine can achieve. To counteract this, you can add additional valves on the cylinder. If more combustion air is needed in the cylinders, then these valves are filled with high pressure. The cylinders are charged with a turbocharger or compressor. Direct injection means that the fuel is injected directly into the combustion chamber via a fuel injector, where it is then mixed with the air.

The amount of fuel injected into the combustion chamber, i.e., into the cylinder. The optimal quantity depends on various factors such as the current engine RPM.

A system responsible for injecting fuel into the engine's combustion chamber (cylinder).

Generally one of two technologies are used in “turbo-charged“ engines: a turbocharger or a compressor. Both fulfil the same need, namely condensing or compressing the air supplied to the engine. By pre-condensing the air and due to the resulting pressure increase, the amount of air supplied to the combustion chamber/cylinder increases. This provides a better fuel-air mix in the cylinder, which considerably increases the amount of energy released through combustion and influences the engine's power accordingly.

Measures the current boost pressure and transmits this data to the ECU. The ECU then calculates the necessary boost pressure as well as the engine's charge state.

The injection pressure is the amount of pressure with which the fuel is injected into the system. This pressure varies greatly between petrol and diesel engines and is also dependent upon the injection system type used in these types of engines. For example, a modern Common Rail diesel engine injects with pressures up to 2,300 bar. In contrast, a direct injection petrol engine uses only around 200 bar. The pressure at which the fuel is injected has a direct influence on the power as well as on the engine's fuel consumption and efficiency. The higher the injection pressure, the finer the nebulisation and the more efficient the combustion within the cylinder.

Measures the quantity of air supplied to the engine. Depending upon the engine, the temperature and pressure are also measured. This makes the air mass sensor one of the most important sensors in the engine compartment. The data gathered here serve to control a number of processes via the ECU.

For diesel engines based on pump-nozzle injection technology (this technology was used up to around 2009 and was often used by the Volkswagen Group, for example), the injection pressure is generated at each cylinder. In the Common Rail technology primarily used today, a high pressure pump is used for injection, which supplies the pressure to all of the injectors. For one, this technology allows for a better fuel-air mix and is also much less expensive for the car manufacturers. The pump-nozzle injection technology is also a form of turbo-charged direct injection.

Measures the current pressure in the intake manifold (behind the throttle valve) and transmits information to the ECU.

A diesel particulate filter (DPF) is a device for reducing particles contained in the exhaust gas of diesel engines. All performance chips from RaceChip can be used with all types of diesel particulate filters. No modifications are necessary.

-

News regarding technology and development

Simply faster is now even better: the new RaceChip GTS

Shortly after presenting their new range-topper GTS Black, chiptuning market leaders RaceChip are now releasing its ...

New top-of-the-line chip tuning product from RaceChip

RaceChip, the market leader in electronic performance upgrade, has expanded its range upward, adding a new top ...

The Future of Throttle Tuning: RaceChip XLR

Updated technology with unique usability, united in a progressive design, point out the innovative strength of RaceChip ...

Simply faster with Quick Nick

Nick Heidfeld was one of the most successful German drivers in Formula 1 from 2000 to 2011 and is currently driving in ...

-

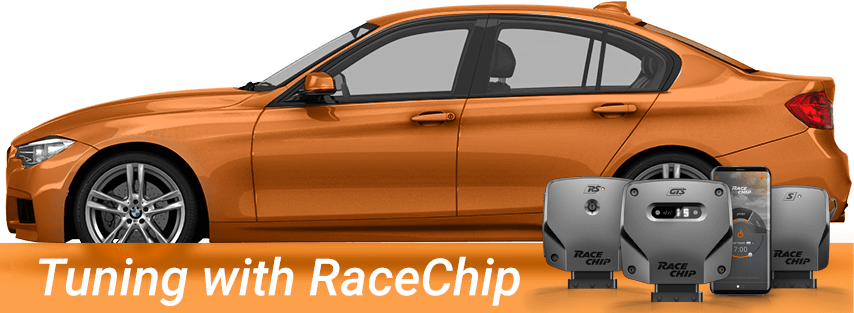

Optimization isn’t just plain old optimization

Box and OBD turning in comparison

In general, two approaches to electronic performance tuning can be distinguished: (1) Performance tuning by directly accessing and reprogramming the engine control unit (ECU), also called on-board diagnostics (OBD) tuning, and (2) optimization with auxiliary control devices also referred to as performance chips, tuning chips, tuning boxes, piggybacks, power chips or power boxes.

Direct ECU tuning and remapping

Performance improvements are achieved by optimizing the electronic signals. This is done via the OBD2 port (also used to read the engine's error memory) or by breaking into the ECU and adjusting or overwriting the manufacturer's software itself, usually referred to as remapping or ECU flashing. In other words, it actively intrudes into the manufacturer's configuration. This remapping technology can be used in all engines with electronic engine controls.

Manufacturer's hardware and software are actively and usually permanently changed.

Manufacturer’s software is changed or completely overwritten thereby often deactivating the protection systems.

Depending on the vendor with or without engine warranty.

Painstaking installation by a fitter without any performance improvement benefits.

Reversion can be done with considerable effort and costs. The change will always remain detectable.

Optimization with auxiliary control device

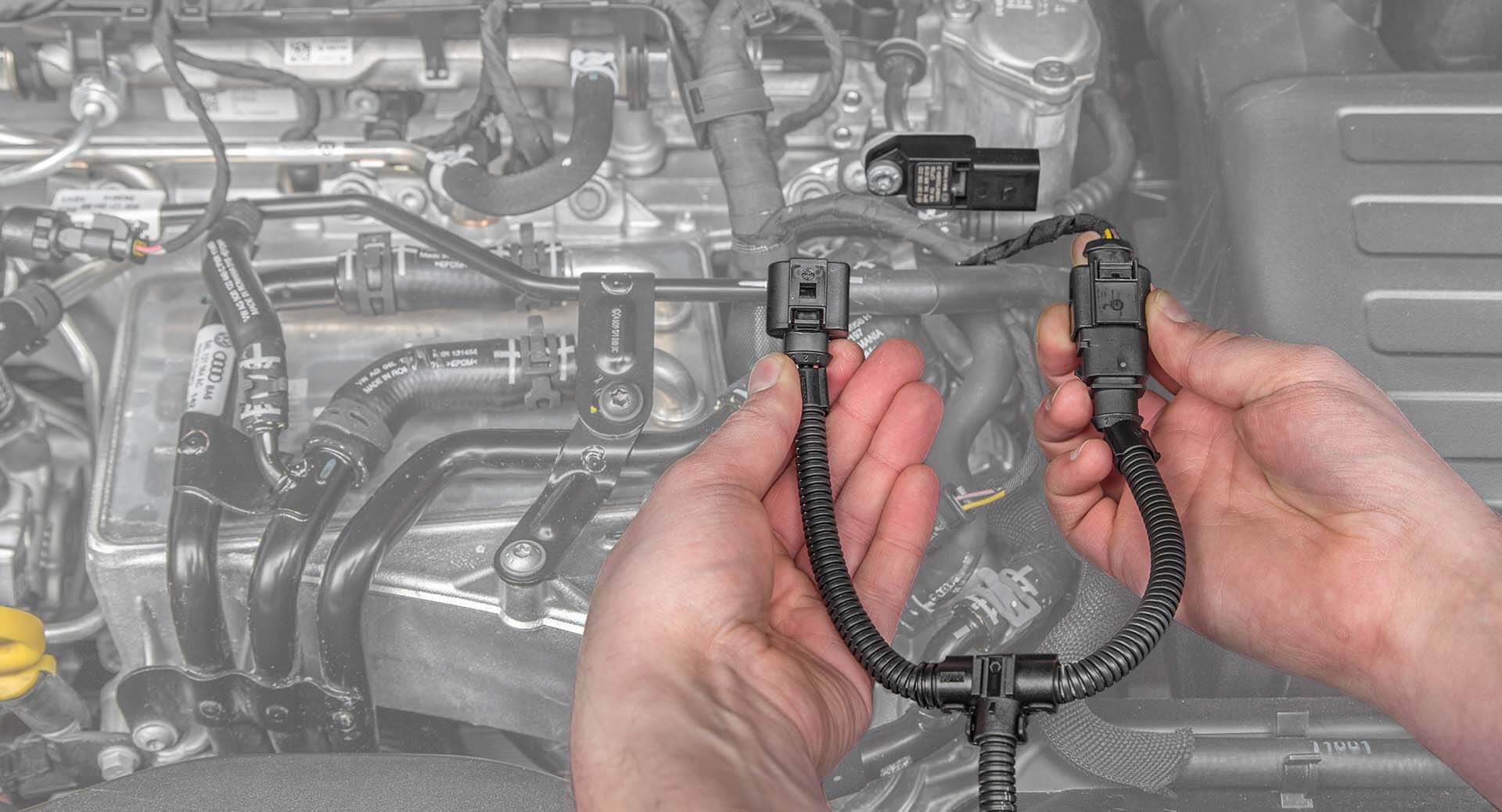

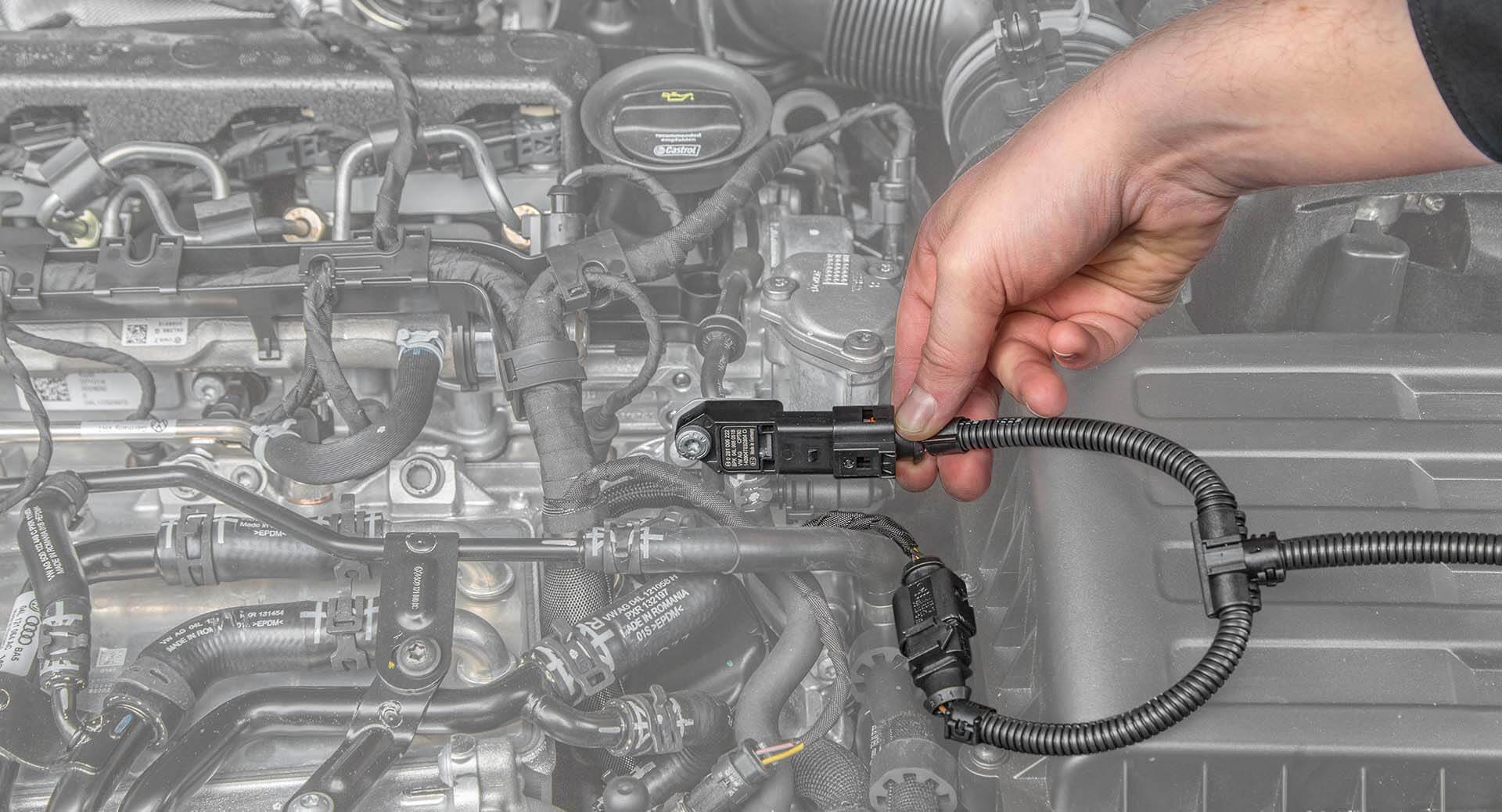

Performance improvements are achieved by optimizing the engine's electronic control signals. The auxiliary control device (a kind of mini-computer) is placed between the engine controls and sensors, which enables performance upgrades of up to 30% using RaceChip’s tuning software. This engine tuning technology can be used in all modern diesel and turbo-charged petrol engines.

Does not change manufacturer's hardware or software.

All engine protection systems remain intact. Performance is optimized only within the power reserves.

Simple DIY installation without any special tools in just 10-15 minutes.

Car can be reverted back to series condition.

Questions about function and installation? Here are the answers

If chip tuning works, then why don't car manufacturers just make it themselves?

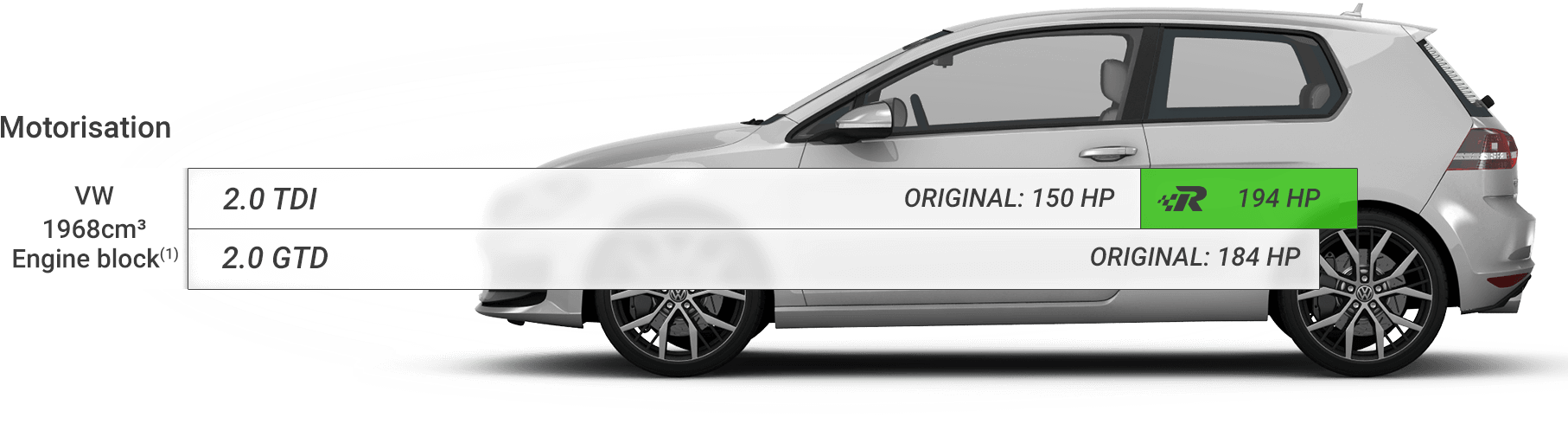

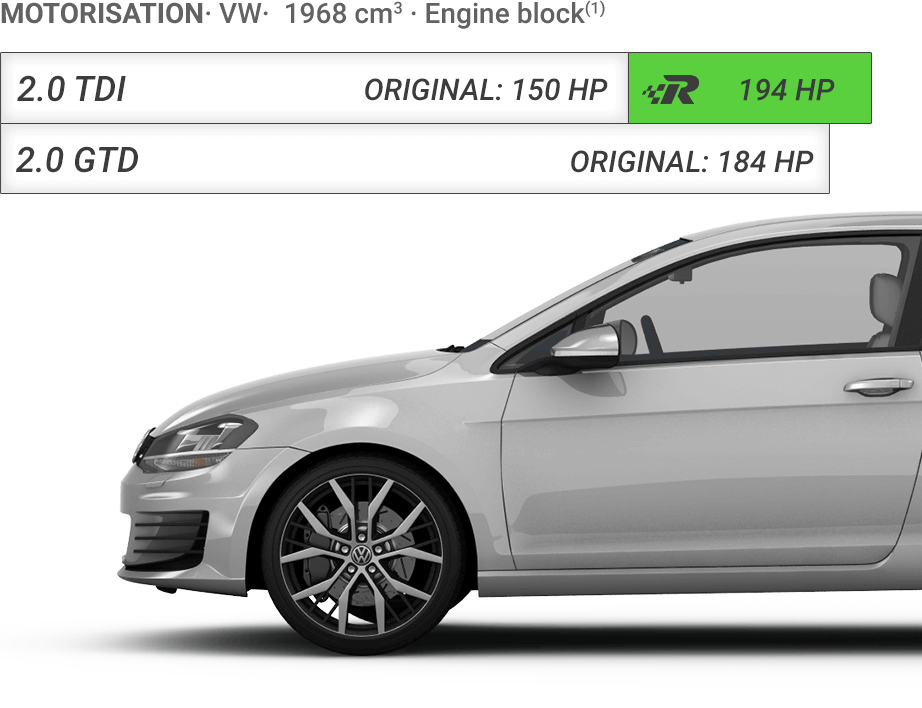

Manufacturers use the same principle. For example, the engine components of a BMW 318d, 320d and 325d are identical. These vehicles are only configured differently through software via the vehicle's control device. Additionally, even top engines provide power reserves for future developments. These robust component layouts provide an excellent opportunity for RaceChip to optimize their settings.

Can I still save fuel despite having more power? How does that work?

Yes, by adapted driving behavior, RaceChip can greatly reduce fuel consumption. The increased torque, which primarily takes place in the lower and mid-RPM range, allows your transmission to upshift sooner, meaning that your vehicle is driven with a lower overall RPM value.

What exactly is Eco tuning?

Eco tuning optimizes a vehicle's motor control to provide high torque very early on. This increased torque allows your transmission to upshift sooner, so that your vehicle drives with a lower overall RPM value. This results in fuel savings, often together with improved power output.

Can my RaceChip be set in such a way that I get maximum reduction in fuel consumption?

Yes. A vehicle's motor controls can be optimized in such a way that high torque is achieved early on. This increased torque allows your transmission to upshift sooner, so that your vehicle drives with a lower overall RPM value. This results in fuel savings.A decisive factor is adapting your driving style with quick acceleration, upshifting as soon as possible (consciously activate gear shifts even with automatic transmissions) and provident driving style.

How is my maximum speed affected?

The maximum speed may increase somewhat, but that is not the goal of our development. Much more, we place value on the improved acceleration capacity of the vehicle. In addition, we do not activate at high torque in order to avoid strain spikes on the components.

How do supplementary control devices differ from ECU tuning?

ECU tuning changes the software on the vehicle's own control unit, allowing it to read and change many of the vehicle's parameters. Often, the forcible opening of the unit is necessary. ECU tuning can only be reversed by completely deleting the controls. Manufacturers and dealers can recognise this procedure! In contrast, the RaceChip's supplementary control unit is installed between the motor sensors and the vehicle's controls. It influences relevant values for our optimization and can be uninstalled at any time. The vehicle is then returned to original condition.

Is there anything special I should watch for after optimization?

Yes! Notice more powerful thrust in your vehicle even at low RPM and adapt your driving style accordingly! Further, you should follow general recommendations for driving your vehicle. In particular, you should not use the engine's full capacity during the first few miles but rather after a warm-up period for your vehicle. Otherwise there are no special restrictions!

Which fuel type should I use after the performance improvement?

RaceChip products tuning takes place on every vehicle with the fuel recommended by the manufacturer. In petrol engines, it may be conducive to use a higher octane fuel, such as 98 octane or higher, for maximum power output. This reduces the risk of knocking (spontaneous ignition of the mix in the cylinder).

Are the optimization systems suitable for vehicles with Euro 5 and Euro 6 emissions standards (EC 715/2007)?

Yes. The functions of RaceChip products are tested and proven even with the latest products on the market.

Can an supplementary control device negatively affect other components or after-market parts in my vehicle?

All our products undergo an EMV inspection, which serves to rule out the possibility of electro-magnetic effects on other components. We cannot rule out incompatibilities in combination with other retrofitted components that may influence performance values. We advise contacting our Customer Service staff if you have queries. It is possible to individually customize the RaceChip product to a customer vehicle.

What should I know about taking my vehicle to customer service at a garage?

We generally recommend completely removing the RaceChip module prior to service in order to allow the garage to provide service based on a series vehicle. You don't have to do anything special for automotive service at the garage, as all of the manufacturer systems remain unchanged with performance enhancement from RaceChip. The chip tuning can be easily re-installed after service.

Does the diagnostic device show that performance enhancement has been installed?

No. A diagnostic device only reads out the data saved to the vehicle's own engine control unit. The RaceChip has absolutely no interaction with the engine control unit. Sometimes diagnostic devices show error messages stemming from the control unit. However, these cannot be attributed to the installation of the RaceChip.

Is it possible to install a RaceChip even without any technical know-how?

Yes. RaceChip products are designed for problem-free installation with the aid of our instructions and videos provided. In some individual cases where users have issues, our customer service is available for advice.

Do I need special tools for installation?

No. You can install RaceChip with no specialist mechanical know-how. In rare cases the air filter box must be disassembled in order to reach the sensor. In these cases we recommend finding a garage if you don't have mechanical know-how. Special tools are not necessary for the actual installation of the chip.

Where is the best place for the module in the engine compartment?

You should install RaceChip products according to installation instructions. Use the existing vehicle cable harness for the auxiliary cable harness. The module itself must be firmly attached and may not be attached on the following areas: Very hot components, strongly vibrating components, moist spaces

What do I do if I'm in doubt during installation?

Follow the instruction manual and check out available videos if needed. If in doubt, contact our customer service.

Can I send you pictures of my engine so that you can help me with installation?

If the pictures we provide are not helpful with assembly, then you can send us pictures of your engine so that we can mark the relevant plug for installation.

I didn't receive a vehicle-specific installation manual with my chip. Where can I get one?

Simply call or email our customer service, and we'll be happy to give you vehicle-specific photos.

The installation manual I received doesn't correspond to my engine. What should I do?

If the supplied installation manual does not provide you with the information you need, you can always request additional vehicle-specific images from our Customer Service staff, either via e-mail or our support hotline.

Can you send me more installation pictures?

We will send you additional installation pictures from our customer service upon request.

Where can I find installation videos for my vehicle?

You'll find a number of vehicle-specific installation videos in our video databank. Our videos can be found here or directly on YouTube on the RaceChip channel.

Does RaceChip offer an installation service?

We do not offer an installation service. However if you contact our customer service, one of our technicians will gladly talk you through how to connect the cable harness and auxiliary device over the phone. This way you can perform the installation yourself within minutes. We are very proud that every customer can install RaceChip chip tuning products without any technical expertise.

Can I have the tuning box installed at RaceChip?

We do not offer this service. If your contact our customer service, one of our technicians will gladly talk you through how to connect the cable harness and auxiliary device over the phone. This way you can perform the installation yourself within minutes. We are very proud that every customer can install RaceChip chip tuning products without any technical expertise.

Can I have the module installed at a garage?

The RaceChip module can be installed at independent garages.

Can I damage anything when installing in my engine?

This cannot happen when you follow proper procedure. Our products are developed according to the Plug&Drive principle. This means that their functions may be complex, but installation should be as simple as possible. All of our products are delivered with extensive tips for installation.

What should I do if the included plug doesn't fit?

Please contact our technical customer support.

What should I do if the control plug doesn't illuminate, even though I'm sure I've done the installation correctly?

Please contact our technical customer support. If the LED does not light up, this can have various causes

Can I remove the tuning and return my vehicle to series condition?

Yes! As soon as you've completely uninstalled the RaceChip product and all plug connections are connected in the original condition, then the vehicle is in series condition. In terms of functionality, your vehicle is already in its series condition as soon as you remove the chip and attach the dummy connector to the wiring harness.

Is my vehicle really in series condition after uninstalling Racechip?

Yes. after complete removal you cannot tell whether an auxiliary device was installed in the engine compartment. A readout of the performance data from a vehicle memory can provide an indication that a performance enhancement was installed. However, this cannot give concrete evidence of the installation of an electronic performance enhancement that uses auxiliary boxes. In addition, this data is read out and assessed in the workshop by very few manufacturers. You can find more information in our Questions and Answers section under the Installation and Removal topic. Our Customer Service staff is of course also available to help and advise you. Other types of tuning (e.g. OBD) overwrite the engine's control software directly, in a way that is recognisable.

How do I remove the plug in the event of deinstallation?

The plug is affixed with a simple locking mechanism at the sensor. Loosen this latch and the plug can be pulled off easily.

Why does the manufacturer's plug look different from the plug you delivered?

Sometimes the plug delivered looks a little different than the vehicle's plugs. However, the plugs can still connect together without any problem and the technical function of the connector will not be affected because we use OEM quality plugs.

Find more questions and answers in the FAQ SECTION

E-Warranty

E-Warranty